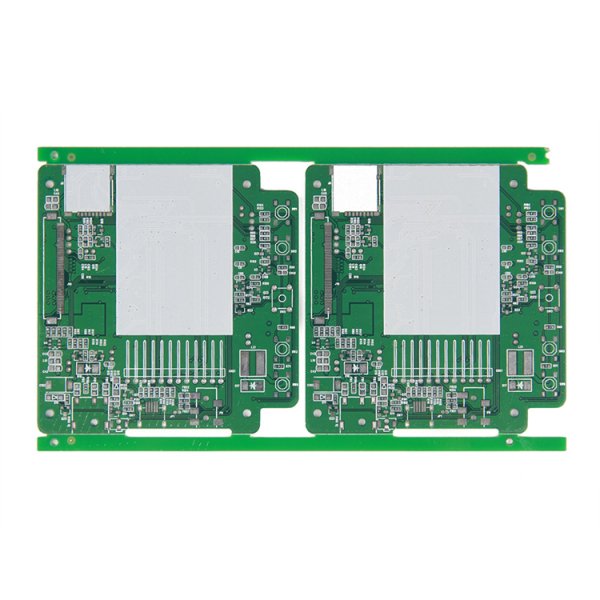

Led Strip Battery Charger Hot Swappable Keyboard PCB

Basic Info

Model No.: EMC certification PCB

Product Description

What is EMC in PCB?

The EMC design in the PCB board should be a part of the comprehensive design of any electronic device and system. It is far more cost-effective than Other methods that try to make the product reach EMC. The key technology of electromagnetic compatibility design is the study of electromagnetic interference sources. Controlling the electromagnetic emission from electromagnetic interference sources is a permanent solution. To control the emission of interference sources, in addition to reducing the level of electromagnetic noise generated by the mechanism of electromagnetic interference sources, shielding (including isolation), filtering, and grounding technologies need to be widely used.

The main EMC design techniques include electromagnetic shielding methods, circuit filtering techniques, and special attention should be paid to the grounding design of the grounding element overlap.

One, the EMC design pyramid in the PCB board

Figure 9-4 shows the recommended method for the best EMC design of devices and systems. This is a pyramidal graph.

Generally speaking, the devices that drive today's electronic equipment have to be mounted on the PCB. These devices are composed of electronic components and circuits that have potential sources of interference and are sensitive to electromagnetic energy. Therefore, the EMC design of PCB is the next most important issue in EMC design. The location of active Electronic Components, the routing of printed lines, the matching of Characteristic impedance PCB, the design of grounding, and the filtering of the circuit should all be considered during EMC design. Electronic Components on some PCBs also need to be shielded.

Third, internal cables are generally used to connect PCBs or other internal sub-components. Therefore, the EMC design of the internal cable including the routing method and shielding is very important to the overall EMC of any given device.

How to carry out EMC design in PCB board?

After the EMC design of the PCB and the design of the internal Cable Connectors I/O Connectors are completed, special attention should be paid to the shielding design of the chassis and the processing methods of all gaps, perforations and cable through holes.

Finally, should also focus on the input and output power supply and other cable filtering issues.

2. Electromagnetic shielding

Shielding mainly uses various conductive materials, manufactured into various shells and connected to the earth to cut off the electromagnetic noise propagation path formed by electrostatic coupling, inductive coupling or alternating electromagnetic field coupling through space. The isolation mainly uses relays, isolation transformers or photoelectric Isolators and other devices to cut off the propagation path of electromagnetic noise in the form of conduction are characterized by separating the ground system of the two parts of the circuit and cutting off the possibility of coupling through impedance.

The effectiveness of the shielding body is represented by the shielding effectiveness (SE) (as shown in Figure 9-5). The shielding effectiveness is defined as:

The relationship between electromagnetic shielding effectiveness and field strength attenuation is listed in Table 9-1.

The higher the shielding effectiveness, the more difficult it is for each 20dB increase. The case of civil equipment generally only needs a shielding effectiveness of about 40dB, while the case of military equipment generally requires a shielding effectiveness of more than 60dB.

Materials with high electrical conductivity and magnetic permeability can be used as shielding materials. Commonly used shielding materials are steel plate, aluminum plate, aluminum foil, copper plate, copper foil and so on. With the stricter electromagnetic compatibility requirements for civilian products, more and more manufacturers have adopted the method of plating nickel or copper on the plastic case to achieve shielding.

Three, filtering

Filtering is a technique for processing electromagnetic noise in the frequency domain, providing a low impedance path for electromagnetic noise to achieve the purpose of suppressing electromagnetic interference. Cut off the path that the interference propagates along the signal line or power line, and the shielding together constitutes a perfect interference protection. For example, the power supply filter presents a high impedance to the power frequency of 50 Hz, but presents a low impedance to the electromagnetic noise spectrum.

According to the different filtering objects, the filter is divided into AC power filter, signal transmission line filter and decoupling filter. According to the frequency band of the filter, the filter can be divided into four types of filters: low-pass, high-pass, band-pass, and band-stop.

How to carry out EMC design in PCB board?

Four, power supply, grounding technology

Whether it is information technology equipment, radio electronics, and electrical products, it must be powered by a power source. The power supply is divided into an external power supply and an internal power supply. The power supply is a typical and serious source of electromagnetic interference. Such as the impact of the power grid, the peak voltage can be as high as kilovolts or more, which will cause devastating damage to the equipment or system. In addition, the mains power line is a way for a variety of interference signals to invade the equipment. Therefore, the power supply system, especially the EMC design of the Switching Power Supply, is an important part of the component-level design. There are various measures, such as the power supply cable is directly drawn from the main gate of the power grid, the AC drawn from the power grid is stabilized, low-pass filtering, isolation between the Power Transformer windings, shielding, surge suppression, and overvoltage and overcurrent protection.

Grounding includes grounding, signal grounding, and so on. The design of the grounding body, the layout of the grounding wire, and the impedance of the grounding wire at various frequencies are not only related to the electrical safety of the product or system, but also related to electromagnetic compatibility and its measurement technology.

Good grounding can protect the normal operation of the equipment or system and personal safety, and can eliminate various electromagnetic interference and lightning strikes. Therefore, grounding design is very important, but it is also a difficult subject. There are many types of ground wires, including logic ground, signal ground, shield ground, and protective ground. Grounding methods can also be divided into single-point grounding, multi-point grounding, mixed grounding and floating ground. The ideal grounding surface should be at zero potential, and there is no potential difference between the grounding points. But in fact, any "ground" or ground wire has resistance. When a current flows, a voltage drop will occur, so that the potential on the ground wire is not zero, and there will be a ground voltage between the two grounding points. When the circuit is grounded at multiple points and there are signal connections, it will form a ground loop interference voltage. Therefore, the grounding technology is very particular, such as signal grounding and power grounding should be separated, complex circuits use multi-point grounding and common grounding.

Contact us if you need more details on Environmentally Friendly PCB. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PCB RoHS PCBA、EMC Certification PCB. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Aluminum Base Board > Aluminum Base Board